On Thursday 29 June, Dr Foley gave a speech titled "The energy transition: Building pathways with science" at the World Mining Congress 2023 in Brisbane. The full speech is below or can be downloaded as a PDF.

It is good to be here as I have had a long association with mining. My dad was a businessman in the sector initially in Bellambi Coal in Wollongong and then Shell, and my own research and its best impact has been in developing a sensor system for mineral exploration that is still used and has assisted in the discovery and delineation of billions of dollars of minerals, especially nickel sulphides and silver.

This week we have heard at this conference about the mining industry playing a leading role in meeting our global climate commitments. The energy transition needs lots of critical energy materials. We have been hearing that this is an opportunity. But to realise this opportunity, it needs more than business as usual, because with this opportunity is the expectation that we achieve the energy transition as sustainably as possible. We will need new ways of working.

We can’t just step up our existing efforts to meet our global climate milestones. What’s more, the world needs to act with speed and smarts to achieve the complexity of the energy transition to net zero in the timeframes needed to effectively address climate change. So, it’s not enough to only reduce emissions. The energy transition must be environmentally sustainable, ensure equity of opportunity and benefits for Traditional Owners of the land, and do this with a circular economy on the horizon. The energy transition needs us to build new pathways, and to achieve this we need a good dose of science.

Today, I want to talk about how science and technology are essential to the energy transition: we need to invest in them. I also want to talk about the role Australia can play, and the impact for the mining industry. Firstly, I wish to acknowledge the Traditional Owners of the lands I’m speaking on today – the Jagera and Turrbal peoples. I acknowledge the Elders who have been looking after these lands. I pay my respects to the old ones who have come before and the young ones coming up, as they will be a very important part of our future.

Australia is making very significant impacts and efforts to address climate change; it is breaking it down into different aspects. I am on the Climate Change Authority’s Board, and its first annual progress report identified that scale is critical. There’s also a requirement for annual Climate Change Statements to be made to Parliament, providing updates on where we are up to. This first progress report notes that while many companies are setting up their own ambitious targets and decarbonisation paths now, there is limited time to demonstrate significant progress. Our timeframe in Australia is set in legislation through the Climate Change Act 2022. The environment is the focus of our National Climate Resilience and Adaptation Strategy.

For economics, Australia’s Clean Energy Finance Corporation is the world’s largest government-owned ‘green bank’, and has mobilised over $11.7 billion for clean energy projects with a total value of around $42.8 billion. The Australian Critical Minerals Strategy was released last week, after wide-ranging consultation setting out the Australian ambition to undertake more mineral processing here in Australia. The circular economy is also in focus: I am part of Australia’s Circular Economy Ministerial Advisory Group. Our final report is due in mid-2024, but we’re already providing active advice to ministers after each meeting. There is also a CSIRO Circular Economy Roadmap.

We have the ‘Powering Australia’ plan, which has a focus on the jobs and preparing our workforce through the transition to net zero, with links to the National Reconstruction Fund, the New Energy Apprenticeship program and the New Energy Skills program. Recently announced, too, is a Net Zero Authority that will be an overarching authority to make sure net zero emissions targets are being delivered in time.

So there’s a broad-ranging effort in Australia to build that robust, coordinated pathway to net zero, and while the exact situation is different in each country, the learnings we’re getting here are applicable to governments and industries across the world. Achieving the energy transition to mitigate climate change is more than dig up, process and use. To get there, there are some daunting issues that need to be considered. We have already talked about scale. Then there’s timeframe, as well as environment, social and governance (ESG) considerations.

We need to consider the economics – which critical energy minerals to mine and which ones to process here, and how to process them and where. There is the circular economy, which will lead to reuse and recycling so that the levels of primary materials will not always be in a high growth state. We also need to develop the workforce to make this all happen. The list doesn’t stop here – we also have to do this with social licence, and ensure equity of opportunity and benefits for Traditional Owners. We’re doing this all while the technology is developing and changing. These aspects all interlink. So our challenge is to find the scenario right there in the middle, where we get all the settings right. We are not going to find that sweet spot by accident: there is a need to ‘science’ our way down that pathway. So, what does a perfect path forward look like? As you can imagine, as Australia’s Chief Scientist, I’m going to look at the Australian opportunity – that’s what I know best – and I want to use this as a case study in this talk.

Australia is committed to a 43% reduction in emissions by 2030. We are committed to reaching net zero greenhouse gas emissions by 2050. When you combine these two commitments, it means that Australia is going to have to decarbonise by about 17 million tonnes of CO2 each year – a rate that’s more than 40% faster than what we’ve achieved to date, over the last 30 years. So, the easy way to do this would be to ‘just ramp things up’. If only it were so easy.

Let’s have a look at what 17 million tonnes of CO2 – one year of cuts – looks like. We could round up the whole Australian fleet of light commercial vehicles – all 3.5 million of them – and get them all electrified; the reduction in emissions would be about one year’s reduction requirement. Now, we only have around 100,000 electric vehicles on Australian roads, so this would be about a 3,500% annual increase in our electric fleet. So, clearly, no one single solution will deliver the reductions required at one time. After all, there is a massive difference in the minerals required for a conventional car versus an electric car – that’s kilograms per vehicle. From just over 30kg of copper and manganese for the conventional car, a single electric vehicle requires 200kg of a cocktail of minerals: copper and manganese, yes, but also lithium, nickel, cobalt and graphite. And there’s a big gap between what the world really needs, and what the current policy settings are enabling us to do.

This graph (below) from the International Energy Agency (IEA) shows anticipated growth in demand for selected minerals from clean energy technologies by scenario – it goes from 2040 relative to 2020.

The blue bars are calculated on the IEA’s sustainable development scenario. The orange dots part way up are where current stated policies worldwide sit. The IEA notes that there is significant uncertainty in projected demand. For instance, for cobalt the demand there could be anything from 6 to 30 times higher than today’s levels depending on assumptions about the evolution of battery chemistry and climate policies. Keep this in mind when we consider some later information on recycling and reuse.

Science and technology are essential to the energy transition. The shift in energy technologies and in critical minerals demand is already happening as we move to a mix of renewables, electric vehicles and battery storage. This is all possible because of science breakthroughs – and we need to be adaptable, because the technology breakthroughs can and do have big impacts on primary production needs. Some of the first solar cells, for example, were made out of germanium. This was in the early 1950s, and this looked like the most promising technology until the first usable silicon solar cell was made in 1963.

I’ve even included another piece of Australian ingenuity. In this picture (below), is the most efficient solar cell in the world, which uses copper instead of silver paste for its electrodes.

I visited this start-up (SunDrive Solar) from the University of NSW earlier this year and they’re currently scaling up production. So that’s one to watch. But the point is, the same thing could happen anywhere. Silicon is straight above germanium on the periodic table – so an easy substitution! Who’s to say that some clever scientist won’t crack the use of, say, making sodium-ion batteries that will be far cheaper than lithium, even if they won’t be quite as light? Or then again quantum batteries? Or solar panels that operate in the dark? Whatever technologies develop or are used, the scale to deliver the energy transition is immense, as will be the scale-up of the materials that need to come out of the ground to build the technologies.

I think we are all still coming to terms with the report that Robin Batterham presented last year that the energy transition, if using only photovoltaics (PVs), would need to cover the area of Tasmania 5 times. And to add to this, those energy systems are likely to be far away from population centres. We are going to need transmission lines, and lots of them, but transmission lines are lossy. And the more we lose through long transmission lines, the more renewables – and the more transmission lines – we are going to need. We will need 10,000 km of new transmission lines for our electricity needs.

In today’s power grids, approximately five percent of electric energy is lost on its way from the power plant to the end user. Well, actually, the losses are converted to heat due to the resistance of the cables. Five percent may not sound like much, but keep in mind that there are currently more than 3,000 large power plants in the world with over 500 million watts output. Consequently, around 150 of those power plants are needed just to compensate for the loss, burning billions of dollars each year just to heat up the planet a bit more. This will mean the same extra level of PVs and wind turbines are needed as we transition away for fossil fuels.

So what if we could stop these losses? Can we have better cables? The answer is – yes. This is where superconducting cables can take up to about 130 amps per strand before becoming resistive – the superconducting lines versus aluminium or copper. Also, they’re much smaller and lighter because of the wonders of superconductivity: even when carrying the same current, a 10mm diameter cable will be replaced by a 6 x 1mm square tape. As superconducting cables are able to carry current with no loss, more power can be carried and there is less infrastructure needed. So the transmission lines that nobody wants in their backyard can change from one type to another.

These new transmission lines are based on a whole new technology. This is an example of a high temperature superconducting tape – it is a quantum technology. Instead of aluminium alloy cables, we will need Hastelloy, a nickel alloy – yttrium, barium, copper – to make up the thin film that is the superconductor layer, magnesium for the buffer layer, and silver – although that is not used in some other brands of HTS cables and copper – noting others use steel. So this is a very different design. These are available now and there are companies in Japan, Germany and USA fabricating the tapes and developing the transmission line system. Have you got the message? We need to have a few more minerals, which means we also need to find them.

In an Australian context, it is actually really difficult to see deep into the earth below the conducting overburden, which makes it difficult to use remote sensing systems to see them. So quantum sensors offer a range of benefits for the mining industry. By providing more accurate and precise measurements, quantum sensors can help miners to identify and extract minerals more efficiently and safely. And this can lead to improved productivity and cost savings for the mining industry. I’ll give you an example, the system which I developed called LANDTEM was used in Canada in the Raglan region – up in the Arctic. It was found to reduce exploration costs by 20 to 30 percent and was able to clearly discover and delineate nickel sulphide deposits that they had previously missed.

Quantum sensors can be used to measure the composition of minerals, allowing miners to better understand the composition of the minerals they are extracting. This can help them to optimise their extraction processes, as well as identify new sources of minerals. Quantum sensors can also be used to detect the presence of hazardous materials, such as heavy metals and radioactive materials. Sensing, used in all industries from biotech and automotives to defence, is already predicted to be a $300 billion market by 2025. Quantum sensing unlocks some amazing new possibilities in areas we know are facing limits, and – with our current known endowments and the potential to find a lot more with quantum sensors – Australia is well positioned to take on this challenge.

And I’ll repeat again, we have immense natural endowments in the critical minerals needed for new energy technologies. So here are the numbers. Australia is number one in the production of lithium and rutile. We are the second largest producer of zircon. We are in the top 5 producers of cobalt, manganese, antimony and rare earth minerals. You might be surprised to know that Australia also produces high-quality research in critical mineral processing, and yet, with all the natural wealth and scientific expertise, we’re still going to need to step this up to meet the needs at hand. For a relatively small country – remember we are 0.3 percent of the world’s population and we do about 4.5 percent of the world’s research – our quality critical minerals processing research output is remarkably high.

Here in Australia, there’s significant government support for the sector. The National Critical Minerals R&D Hub is an Australian Government-funded initiative that coordinates and aligns critical minerals research across CSIRO; ANSTO; the Department of Industry, Science and Resources; and Geoscience Australia. The Hub was established last year to address technical bottlenecks across the critical minerals value chain and work with industry to focus R&D efforts on national priorities. It will unlock new sources of economically viable critical minerals and diversify supply chains of interest to Australia and our allies, and create Australian IP in mineral processing.

The current work programs include critical minerals assessment work from CSIRO in high purity. The work with ANSTO is in high-purity silica PV and electronics, and rare earth mineral processing development. What I want to note here is that this is not early-stage research – this is directly to support industry. So the support by Government via the public-funded agencies is really focussing on that. We also have the Government supporting collaborative research centres (CRCs), which bring researchers and industry together. The Heavy Industry Low-carbon Transition (HILT) CRC is going to be running up until October 2031 and received nearly $40 million from Government, which is heavily leveraged by industry funds. HILT has a focus on decarbonisation, such as that needed to produce ‘green iron’ products from magnetite ores, low-carbon iron exports from the Pilbara ores, low-carbon alumina using calcination and Bayer processes, integrated CO2 capture and re-use technologies and methods for industrial processes. They are also looking at technologies to lower carbon emissions through synergistic production of industrial chemicals and fuels. Then the most recent one is the new Curtin University-led Resources Technology and Critical Minerals Trailblazer project. This has $50 million from the Government and is supported by the university and industry partners to a total of over $200 million. Curtin University is partnering with the University of Queensland and James Cook University, and 33 company partners across Australia involved in the value chains requiring lithium, nickel, cobalt, vanadium and hydrogen resources.

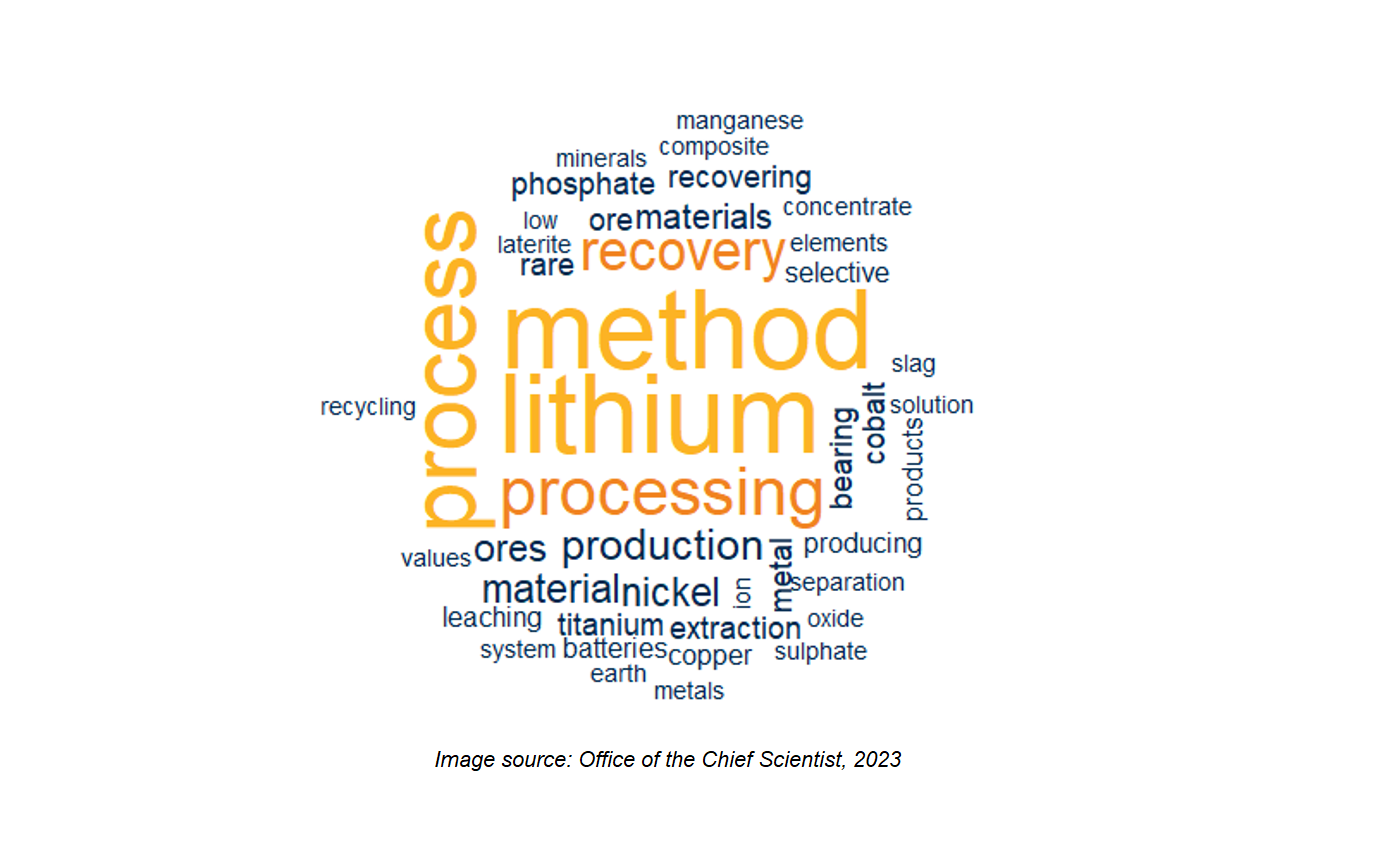

Knowing that we can't do it all ourselves, partnering internationally is really critical. I'll give you an idea of just how strong our partnerships are worldwide. Australian researchers have published a large number of papers that relate to mining and mineral processing, metallurgy and metallurgical engineering with partners in 20 different countries around the world. And we are developing great IP, too. This word cloud (below) shows all the patents produced over the last 5 years in the Australian market. You can see there is a big IP jump for lithium. If you have keen eyes, you will see nickel, titanium, cobalt, and copper there as well as methods and processing.

Also in Australia, there is a really deeply embedded value that we have here, and that is, that we want to do this with the ESG context – considering our environment, the social, and the governance qualifications. For example, Traditional Owners are recognised in Australia and we want to see genuine partnerships and benefit sharing between the critical minerals sector and Traditional Owners. It is worth remembering that more than 60 per cent of national resources projects operate on land covered by Native Title claims or determinations. Traditional Owners and communities have had absolutely strong interest in the growth of the critical minerals sector. And they want to see strong partnerships developed because that is absolutely essential if we are going to hold positive social license.

Many critical mineral companies are already making tangible steps in this area to provide economic and employment benefits for First Nations peoples. This includes direct employment opportunities and goals for Indigenous employment; workforce and career development programs and also procurement from local First Nations companies. The mining industry is absolutely crucial to this, but one thing I want to raise is that it must adapt. It must be innovative and agile. And the sector will need to invest in R&D to make sure we can commercialise and scale up these new technologies.

I want to give you some examples beyond what I have talked about so far. You have probably heard this week that, suddenly, vanadium is on the agenda. We need agility in the mining sector because we are seeing technologies come through that have need for new primary materials. And that is highlighted by vanadium batteries. If you look at CSIRO’s critical minerals roadmap that came out a few years ago, it did not have vanadium as a big one. So last year the Australian company North Harbour Clean Energy announced a project to build a 4MW/16MWh vanadium redox flow battery – the precursor, they hope, for the development of a 200-job assembly and manufacturing line for such batteries here in Australia. Vanadium flow batteries are an Australian invention and are seen as a good pathway forward for grid-level storage due to their long lifespans, safety, and favourable pricing. While they can’t provide the same power as a lithium battery, they excel at energy storage. So that is an example of where suddenly something came from nowhere.

We also need to think about circular economy practices, because they are going to have impact on the mining industry and our need for primary mined materials. Circular economy planning is having full recycling and reuse pathways designed into new products and technologies right from the very beginning of their development. We are moving towards a 'no more throw away' culture. We need to know what end-of-life looks like even as we’re creating our early prototypes.

It’s a huge undertaking because it brings in questions of design, materials selection, life span, future technologies development, user behaviour, corporate behaviour, product re-collection, materials recovery and separation, recycling and reuse – and that’s before we’ve even built the first product. Under a circular economy, we may see batteries from electric vehicles getting a second life as a home storage battery for a further decade before they are recycled. This is happening in Japan now. But in that case those minerals are effectively out of circulation for a whole extra decade and our primary demand for mined critical minerals will not fall in that time. If the circular economy case prioritises recycling for a product on a regular, short timeframe, then the primary demand will fall as recycled minerals enter the supply chain. And each mineral will be treated differently.

This is an area of complexity and having a whole-of-system approach will be needed to make sure we have the balance of materials supply. This is going to be tricky. Not surprisingly, CSIRO has already come up with some early work considering what impact the circular economy might have in this regard, particularly for the treatment of electric vehicle (EV) batteries. Their report looked at three main scenarios. The first is a current trends scenario, with medium battery take-up, moderate EV take up and 100% recycling of batteries. The second is a rapid change scenario, with rapid battery take-up, a full EV fleet by 2038, and 100% recycling of batteries. And the final one is a circular economy scenario, which had the same take-up rate as current trends but incorporated second life usage for 60% of batteries. They found a marked difference in mineral demand is forecast under those three scenarios (see below).

So let’s start with lithium. In all three cases, lithium demand soars above current production levels. The current trend setting sees a long, sustained period of demand, as growth in demand is ameliorated by the reintroduction of recycled lithium. The rapid change scenario sees an early peak in primary demand, before a sharp drop as recycling kicks in. And the circular economy setting provides the highest and latest peak of all, as lithium stocks remain in use for longer periods during the transition before entering the supply chain as recycled material again.

But each mineral is remarkably different. Looking at nickel – it's not so different, but when you look at cobalt you can see that there’s a glut. Remember what I said about cobalt and how much we really need? That is a really good question. So remember that this is specifically looking at EV batteries, and ultimately only a small subset of the transition to zero, but you can already see the big flow-on impacts that these kinds of settings are going to have.

I want to finish up now and go through what I want you to take away today. And that is that the world needs to act with speed and smarts to achieve the scale, timeframes and complexity of the energy transition to net zero. It is not enough to only reduce emissions. The energy transition must be environmentally sustainable, ensure equity of opportunity and benefits for Traditional Owners, and be part of a circular economy. Science and technology are essential to the energy transition. The shift in energy technologies, and thus in critical minerals demand, is already happening as we move to a mix of renewables, electric vehicles and battery storage. But the energy transition is still in its infancy. And to build the scale and complexity of our future energy system, we need new technologies and new ways of operating.

Australia is well positioned to take on this challenge. We have immense natural endowments in the critical minerals needed, as well as the new energy technologies, and we also have that strong and responsive research sector with strengths in mineral research and development. The mining industry is absolutely crucial to this. We need to work with them so that they can adapt as things change and be innovative and agile. The sector, I hope, will invest in the research and development to make this happen. The future of mining cannot be business as usual. We need to be thinking of mining in a broader context and doing it with a systems approach. And this is where I hope that the investment will be there to make that happen.

I want to finish up by saying I know I am only Australia’s Chief Scientist for so long. So watch this space. I am really tempted when I finish this job to jump back in the lab and make sure that I make some better sensor systems, so that we can find many more minerals that help us deliver on the great ambition we have for using renewables, batteries, PVs and all those technologies – to make sure that we can transition and make sure that severe climate change does not impact our lives.